Particulates in Pfizer

Yet ANOTHER contaminant and differences between Process 1 and 2

On X, Melissa McAtee who is a Pfizer whistleblower and worked in Quality Control, posted a video of a Carpuject. A Carpuject is a syringe device for administering intravenous meds Melissa McAtee video

In this video you can see a black particulate in the syringe. Melissa asks a good question. Did you know that there’s an acceptable amount of PM (particulate matter)? That is, there is a level of particulate matter that is acceptable to the regulators for IV products?

Particulates

What are “particulates?”? Where do they come from?

Particulates are found in parenteral pharmaceutical products, mostly given by intravenous injection but also intra-muscularly like the mRNA vaccines. Parenteral products are specified to be essentially free of visible particles and subdivisible particles by the regulatory agencies. Here are the FDA Guidelines Inspection of Injectable Products for Visible Particulates

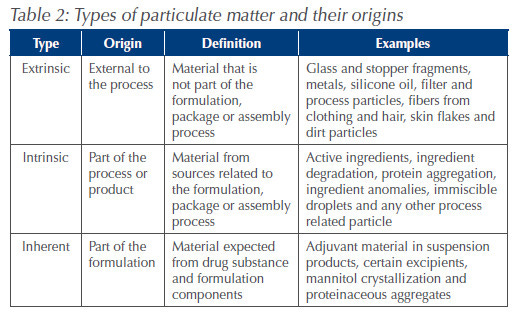

Particulates refer to mobile, undissolved particles other than gas bubbles that are unintentionally present in an injectable product. They vary in nature (e.g., metal, glass, dust, fiber, rubber, polymer, mold, degradant precipitate) and can be divided into 3 categories:

Particulates have been monitored in drugs for a very long time so none of this is new and was included as a critical quality attribute for the modRNA vaccines. There are also compendial standards that are detailed and very well established. Intrinsic/inherent particles are typically associated with a lower risk compared to extrinsic particles.

Here are the definitions:

Visible particles are defined as those that can be detected under controlled conditions by the unaided human eye. The best-case threshold for the human visual identification is roughly 150 μm. Each vial must be essentially free from visible particulates when examined without magnification against a black background and against a white background. This is what Melissa is doing in the video above.

Subvisible particles are those between 25 μm-150 μm, a visible gray zone which ranges from submicron particle size up to the visible threshold. This requires other methods for particle counting other than the human eye (which is better than electronic eyes BTW).

Then there are the limits of how many particles you can have per volume for visible (really none) and subdivisible particles.

What Are the Risks of Particulates?

Honestly, I think only pharmaceutical manufacturers and hospital pharmacists care or know. But, risks of particulates have been known for a long time and is one of the most common cause for product recalls. The risks are based on the following:

Infection and inflammation due to local or systemic infections caused by the presence of micro‐agents or endotoxins as mentioned by

here endotoxin micelles.Physical presence of a particle may cause inflammatory response directly or through associated substances leaching from the particle that cause direct tissue injury

Particles might also stimulate untoward immune responses such as systemic inflammatory responses (SIRS), allergic reactions or anaphylaxis

Tissue damage can arise from the occlusion of the affected vasculature (clots)

These risks are more likely in ICU patients receiving lots of IV fluids and in babies and neonates. I have seen docs and nurses “core” the rubber stopper with the needle and you can see bits of rubber floating around. Most are blissfully unaware BTW. Risks are much lower with IM drugs or vaccines as they are not given continuously or in large amounts.

See: Medical risks of visible particles

Subdivisible particles in protein or biological drugs (<10 microns) are a special risk since they represent protein aggregates and can form anti-drug antibodies. Do formulations of LNP particulates represent a specific risk? Or other particulates from manufacturing these products?

What do these particulates look like?

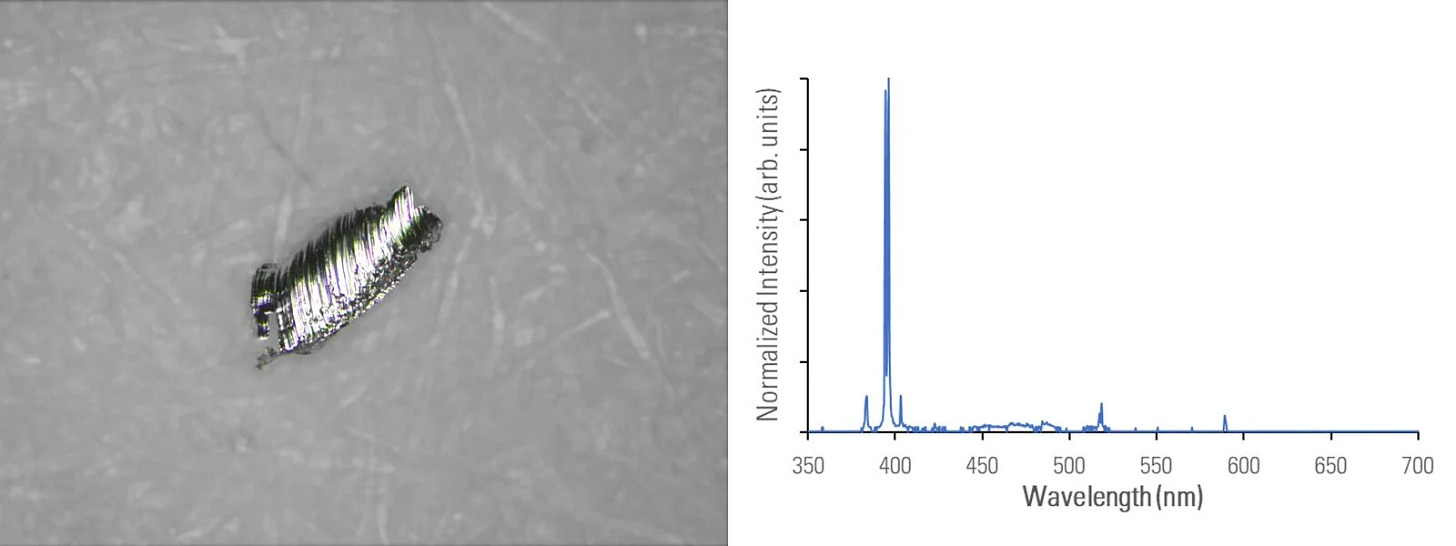

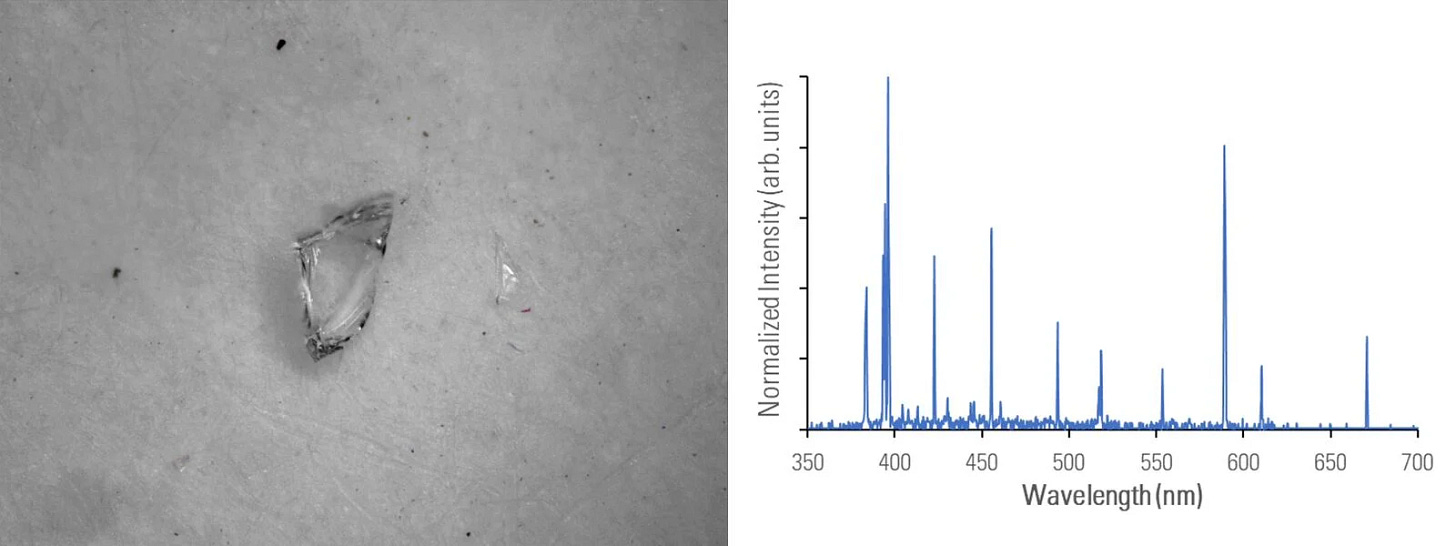

The first is a pic of aluminum alloy probably from the container cap crimped on the vial. The second is a particle of glass. Both would be considered extrinsic particles. Particulate Contamination

There was this study done in Italy on vaccine quality which cause quite a stir at the time. They identified micro- and nano- contamination in the vaccines which represent particulate contamination. What is particularly interesting is what these particles are doing and reacting with biological material within the vaccine and could possibly represent a risk for autoimmune disease etc. As in the examples above these are extrinsic particles. New Quality-Control Investigations on Vaccines: Micro- and Nanocontamination

Figure 5 Show particles surrounded by an organic compound. They are composed of Lead (a,b), Iron, Chromium, Nickel (stainless steel; c,d), Copper, Tin, Lead (e,f). The arrows show the points where EDS spectra were taken..

Pfizer: Particulates Between Process 1 & Process 2

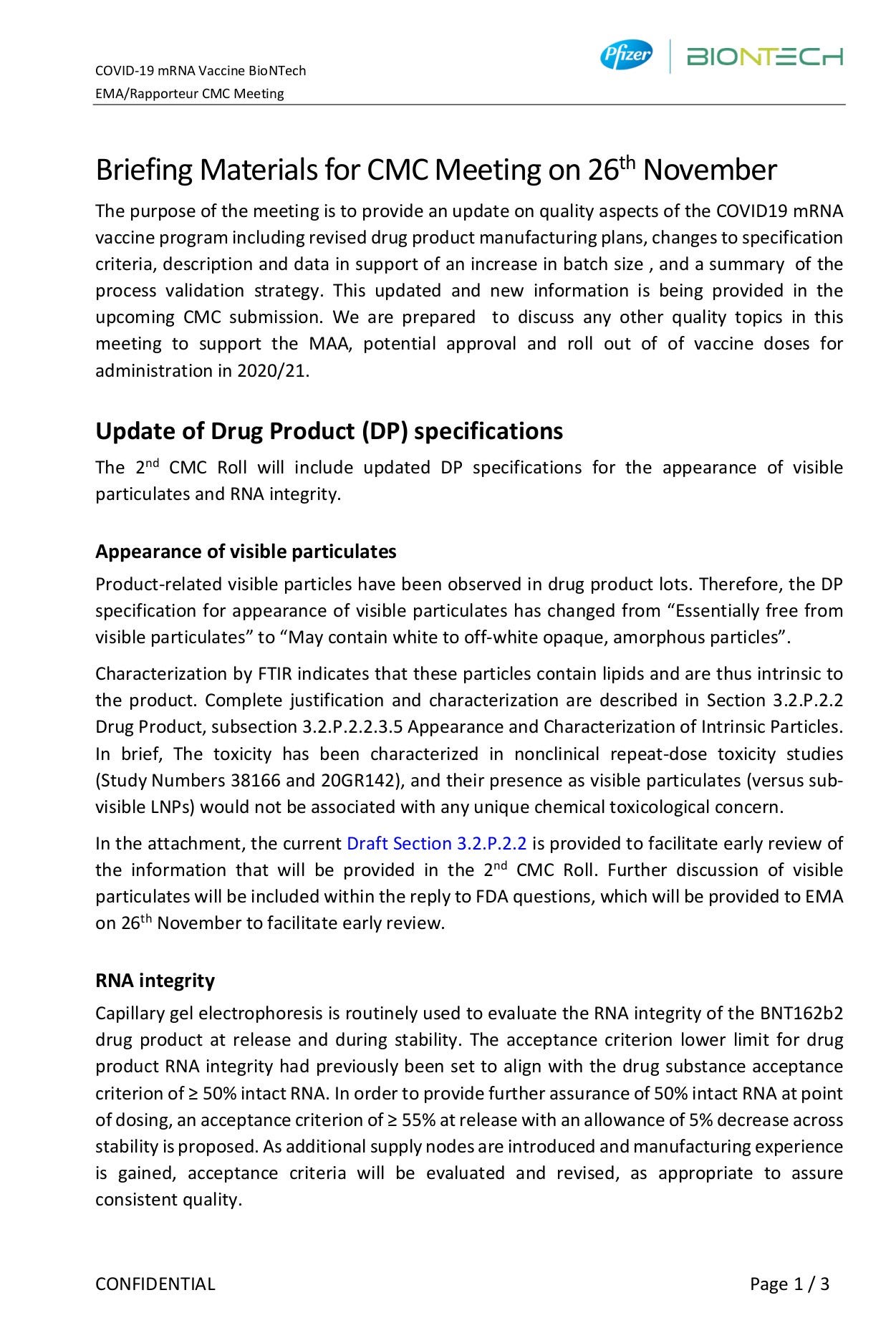

Ok, now this is where it gets interesting. The EMA got told JUST BEFORE the they were ready to approve the Pfizer product that there was a NEW PROBLEM in addition to the mRNA integrity issue (see bottom paragraph).

November 25, 2020. PFIZER SAYS THERE IS AN ISSUE WITH VISIBLE PARTICLES IN THEIR PROCESS 2 LOTS.

Oops! What are these visible particles (remember they are >150 microns) so they are failing the compendial standard.

So the specification changed from Process 1 *essentially free of visible particulates* (which is the compendial standard BTW) to *May contain white to off-white opaque, amorphous particles.* for the Process 2 lots. Because they are intrinsic particles they are no big deal, right? So as with other critical quality attributes, the acceptance criteria just changed. No need for Pfizer to meet well established compendial standards.

So the FDA looked at this issue.

How does Pfizer answer?

So are these LNPs? Broken up LNPs? These are 150 microns or 150,000 nanometers so not small. Plus they occured POST FILTRATION with a 0.2micron filter (200nm). And they FLOAT TO THE TOP of the mixing vessel. So if you happen to get a vial that was filled at the end of the filling process you might have gotten a whole lot LESS mRNA since the LNPs had broken apart?

Is this why some lots were less toxic than other lots? The LNPs had broken open and the mRNA spilled out so there would be no translation of the mRNA because there would be no transfection.

Also, mixing of the LNPs with the sucrose solution they are in has to be slow. Because if they mix at high speeds even for 5 minutes the LNPs fall apart as well. Stability of LNPs and protein expression

Pfizer’s Drug Administration Directions

Since Pfizer (and Moderna had the same issue BTW) had these issues with particulates etc, it is interesting to note how they were to be addressed by regulators as administration guidelines for the vaccinators.

Visually inspect each dose in the dosing syringe prior to administration. The vaccine will be an off-white suspension. During the visual inspection:

Verify the final dosing volume of 0.3 mL.

Confirm there are no particulates and that no discolouration is observed.

Do not administer if vaccine is discoloured or contains particulate matter.

Hmmmm, does every nurse or doc examine the vials? Pharmacy techs always do and pharmacists normally do but I bet it is cursory. Did Pfizer know these particulates may be particularly toxic?

Why Did This Happen with Process 2 Lots and Not Process 1 Lots?

This is a very good question that took a while for Pfizer to figure out. Firstly, vials in Process 1 lots were not frozen. They were in fact flown in by PRIVATE jet to the sites doing the clinical trials. Race to develop the Pfizer vaccine. Now that they were frozen and thawed and large particles were seen.

Well, this goes back to the PBS buffer AGAIN. This buffer has sodium and potassium in it which is a normal good phsyiological buffer. BUT, electrolytes do not play well with a colloidal dispersion represented by the vaccine. This is pharmaceutical sciences 101. I guess flying it around in private jets stopped them from thinking of this. Moderna figured this out early.

What happens is that significant pH fluctuations can occur in phosphate systems containing sodium ions after freezing, to as low as pH 3.6. When there are pH changes, and a high relative concentration of electrolytes compared to the lipids, this can lead to aggregation, and agglomeration, and, maybe even flocculation (BIG FLAKY particles)

Segalla on chemical-physical criticality and toxicity of LNPs

So if the LNPs aggregate or agglomerate with each other to form larger, heterogeneous “particulates” with a polydispersity index (range of size), the material, or part of the material, may not enter a cell and/or may deposit in tissues or organs. Can this have led to the high rates of adverse events like clotting seen especially with the purple top vials which had the PBS buffer? This is my current hypothesis I am working on. So these are not intrinsic particulates per se, because they are forming AFTER the formulation is stabilized and represents a failure of the formulation.

So the change in buffer to Tris was not only for improved storage and no dilution, but really to

decrease risk of lipid adducts (see my previous substack) AND

decreasing risk of agglomeration and clumping of the LNPs leading to destruction and leaking of the mRNA.

Nanoparticles are Intrinsically More Toxic

This issue goes back to PHYSICS.

As size decreases, surface area increases, thereby speeding up dissolution of soluble particulates and exposing more of the reactive surface of durable but reactive particulates.

Makes sense, doesn’t it? ALL nanoparticles are toxic in nature unless there are mitigations. And even then. There is more but really requires another substack in which I will discuss CARPA and other issues and most importantly this paper and that of Segalla.

A pathologist's view of nanotoxicity No it is not Dr Burkhadt but after reading this you can see why he was also so concerned.

Pfizer Addressed the Risk of External Particulates

Remember those extrinsic particles of aluminum and glass above? Well the glass can delaminate especially when store at these ultra-low temperatures. So they had to us special glass vials that were developed by Corning.

In October 2019, a leading pharmaceutical manufacturer received FDA approval of Corning Valor® Glass for use as a primary package for a marketed drug product. Pfizer recently signed a long-term purchase and supply agreement for Valor Glass. The grant from BARDA was announced in June of 2020 with the funding to be used to help defray the costs to expand and establish Valor Glass production capabilities.

Well, how convenient! Talk about coincidences. NOT Lipid-Based Nanoparticles for Drug/Gene Delivery: An Overview of the Production Techniques and Difficulties Encountered in Their Industrial Development Reduces glass particulates!!

Summary

Nanoparticles are intrinsically toxic

Particulate contamination is a problem in manufacturing overall

Process 2 lots showed a real problem with particulates and agglomeration which were explained away by Pfizer at first

Pfizer eventually changed buffers which helped with helped with this issue but represents a material change in the vaccine. Talk about flying the plane while designing it. I call this a Process 3 change combined with the Lipid Adduct issue.

Moderna had its own issues with particulates which will be addressed in another substack

Some potential issues with deep freezing were ANTICIPATED and supported with BARDA funding.

KNOWINGLY KNOWINGLY KNOWINGLY

Pray the rosary.

the story gets dirtier by the day. It is almost a miracle that so many people are still alive with all that has washed up so far. I read a few days ago that 1.7 million people died tho, probably from all the jabs together, but some say there might be as many as 7 million. I know 2 who probably died from them.

I pinned a link to this article to my recent post here:

https://francesleader.substack.com/p/in-2018-italian-scientists-were-silenced